Modelling Multiphase, Multiscale Resin Flow in Composites

Start Date 14/08/17 - Finish Date 06/05/22

Developing a Computer Model to Simulate the Forming of Composites During Infusion Manufacture

In infusion manufacture, optimising the cure cycle time is a complex challenge, as too quick a cure can lead to porosity, whereas a slower cure reduces output and increases cost. The aim of this project is to create a computational model to simulate the flow and cure of liquid resin within a composite fibre bed. This will allow the user to alter parameters to optimise the cure process, without the fabrication of many costly prototypes.

Numerous factors affect the infusion and cure processes, so this computational model needs to take many parameters into account, including:

- Resin flow rate

- Local temperatures

- Time

- Cure rate

- Resin viscosity

- Displacement

- Fibre direction

To provide a complete picture, the model needs to encompass the infusion stage of manufacture, as this is when voids can occur in the resin. This requires tracking the fluid front in a two-phase fluid simulation (i.e. the air being expelled and the liquid resin being introduced).

Recent Updates

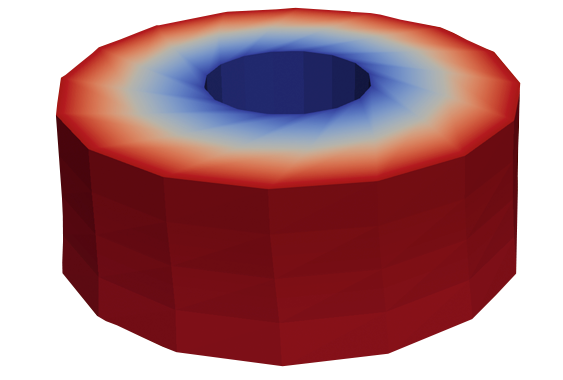

A three-dimensional, linear model has been created in Matlab, encompassing fibre compaction, fluid pressure, temperature and resin cure. A non-linear model of fibre compaction has now been created using FEniCS, to which will be added the fluid behaviour of the resin.

Collaborators

- Professor Tim Dodwell, Academic Principle Investigator, https://emps.exeter.ac.uk/engineering/staff/td336